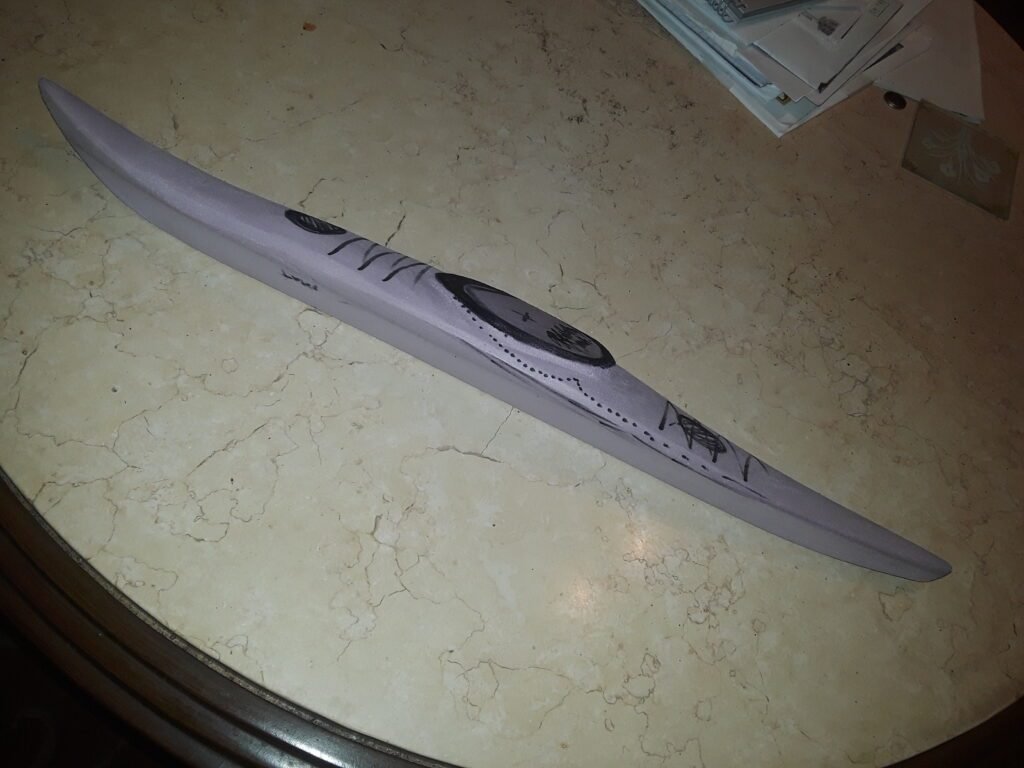

I ambitiously attempted to build a custom 17′ fiberglass sea kayak. I started with the a small mockup of the design and after a successful mini prototype, pursued the full-scale project (*bad idea*).

For the fiberglass mold, I used several 4-ft x 8-ft x 2-in Polystyrene foam insulation sheets, cut and glued in layers to into the kayak’s shape, after much carving. I used a wooden internal frame to create the cockpit (which enabled me to use less foam) and a firm mounting and carrying point on the mold. Something I didn’t quite anticipate was the sheer mess the foam would produce. I experimented with fiberglass and epoxy resins and fabrics. It was around this time that I patched a side of the fiberglass bed on the Ridgeline truck project.

This project ultimately failed due to incompletion. As I began working full-time and had moved out to my own apartment, I didn’t have the time or capacity to continue it. Someday I will begin again, maybe even a 3D Printed Kayak…