Consider this a design ride-along if you will where I share step by step how I came about creating this product. I hope to create on of these for all my designs and products. More coming soon, I guess.

The Problem

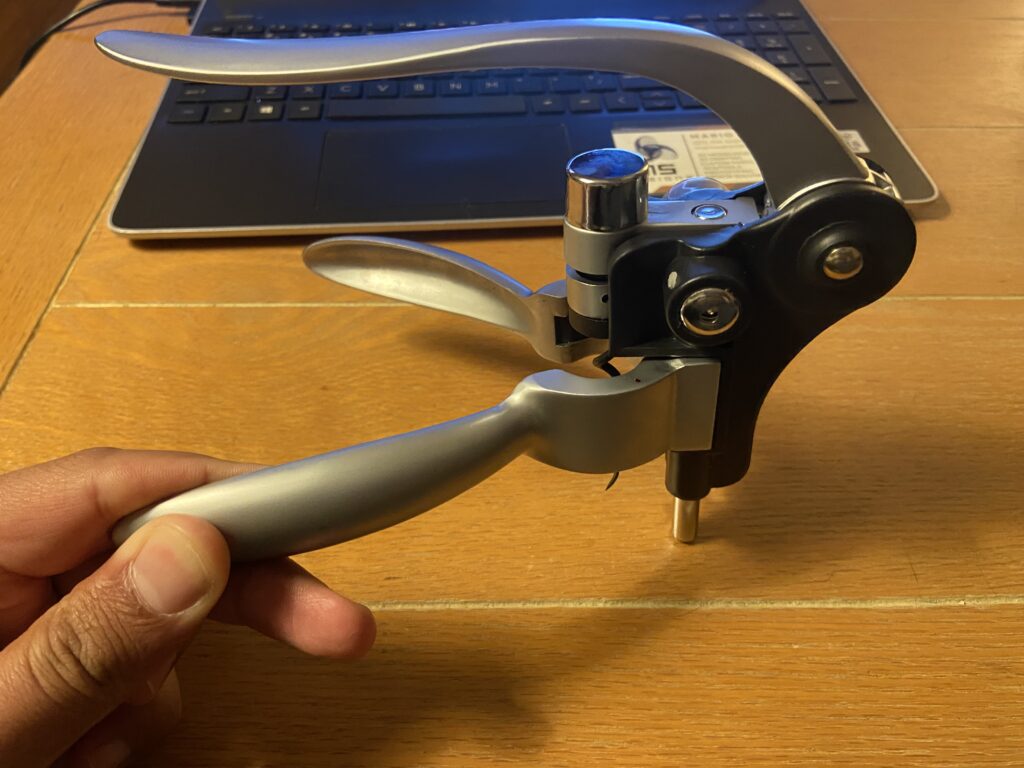

This is a lever corkscrew bottle opener that I purchased from Goodwill. Its base disappeared during our move and so I wanted to create a more effective and aesthetic base for it.

The Physics of the Scenario

As you can see, it falls forward when left alone because all of the mass is concentrated in front of the round dowel (main axis). This is known as its center of gravity (cog) or center of mass. Of course, unless I removed the parts, weighed them, did a ton of math, then I could figure out where the cog is with more accuracy.

However, with some feel and intuition, I estimated that the cog of this product is going to be forward, and slightly ahead of the center. Pictured below.

The base therefore had to extend beyond its center of gravity so the opener doesn’t tip forward.

I made a few measurements, taking into account the depth and the two different diameters, constraints such as interferences like the corkscrew.

I decided to create a base that extends about 75% the length of the opener to allow for ample support. This only works if the arms and lever are over the base, however, the moment they swing around 180 degrees, it will tip again.

Account for Future Errors or Product Failures

So noticing the flat section pictured below, I wanted to incorporate it into the design as a physical constraint to prevent it from swinging and therefore tipping.

I love adding circles and arches, with rounds and chamfers in my design to give it a modern and sleek appearance.

This is what the 3D file looks like on the 3D Printer slicer ready for printing:

Measure twice, cut once or in this case print once

Okay, honest mistake – I made an error measuring the diameters and providing a large enough tolerance. I want a tolerance that offers a loose fit, but not too loose that it wobbles and loses stability.

Note: if I was printing a part that took longer than 1 hour, then I would isolate the parts that matter such as touching surfaces, and print them separately to quickly test fitment.

I wasted 1 hour and some plastic with that mistake. I remeasured and added 0.25 – 0.30mm to the actual dimension that is interfering with the product (or the sections that fit into the base).

Here is the final design!

Well here’s a thought – I decided to design a base as the solution to having a way to stand the opener… but I jumped to a solution of a base because it came with one that I didn’t like.

Could I have created another solution instead of a base?

See this and my other simple inventions and 3D printed solutions!