Still a draft, published 🚧

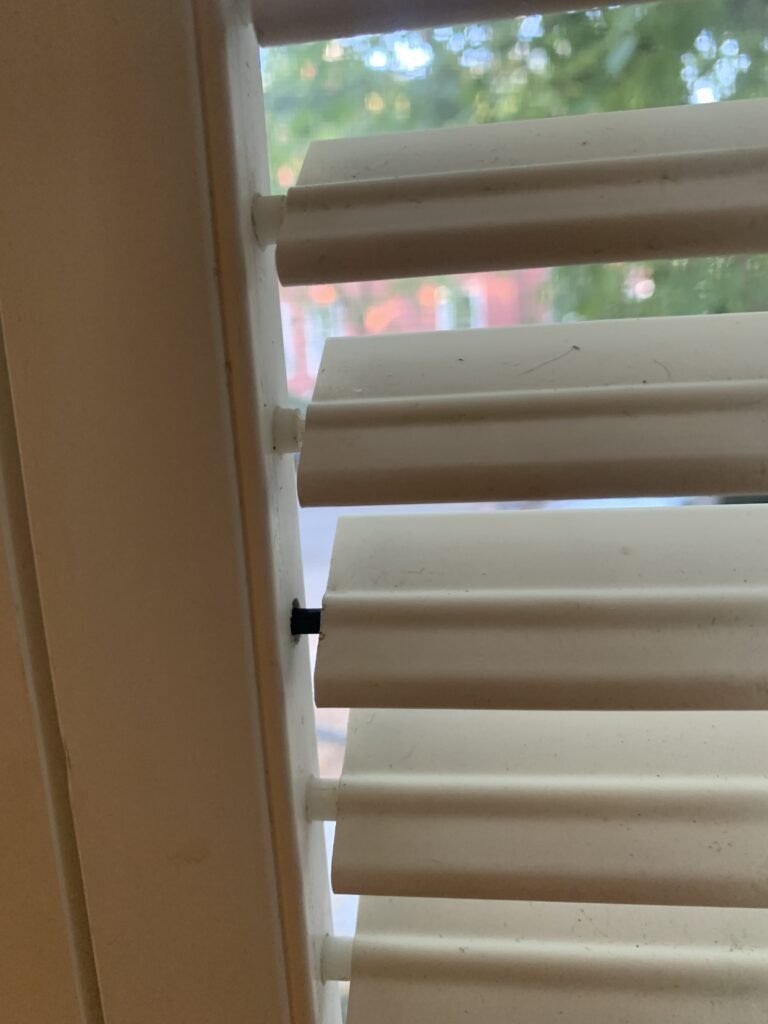

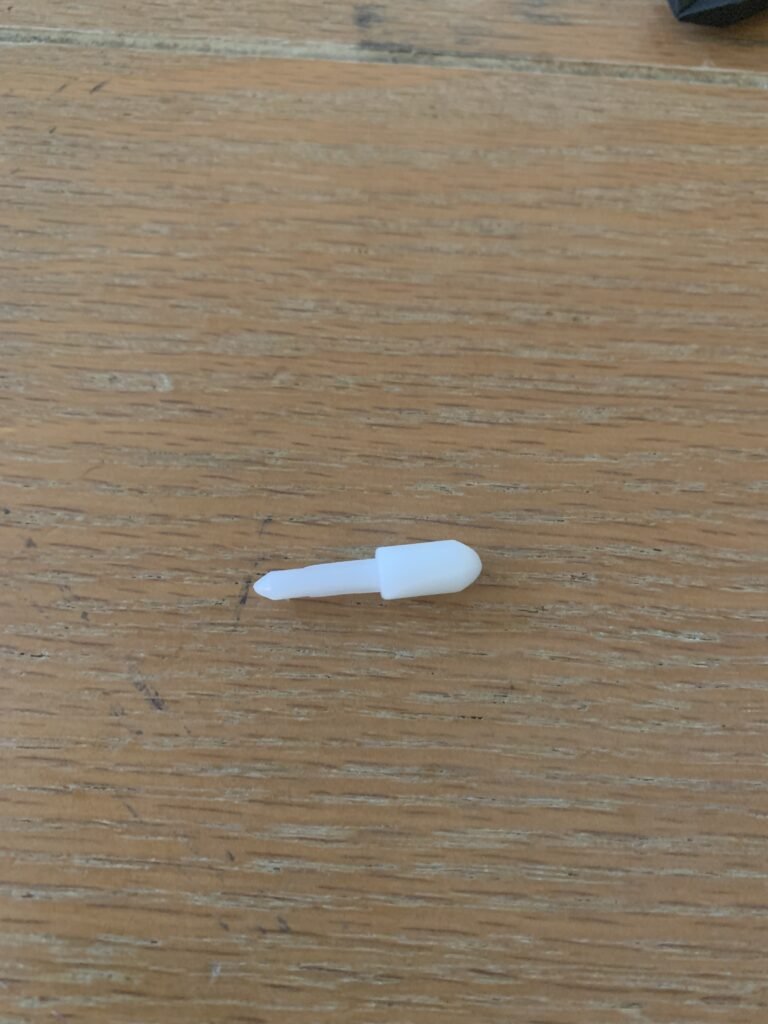

A while ago, I created a solution to fix my apartment’s window blinds which was my version of that white round piece. It was more than just extruding two concentric diameters. A three minutes total print and very little material, however more thought than what meets the eye.

This is how I designed it.

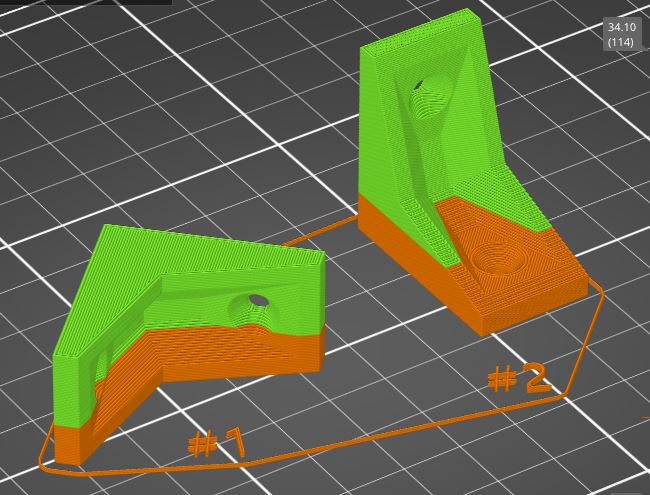

I printed this part in two different orientations to illustrate a point.

I had to create one simple modification to its design allow me to 3D print them. I had to create a flat surface in the larger bottom portion flush with the small diameter upper portion. I’ll tell you why. As you see below, I tried printing in two different orientations.

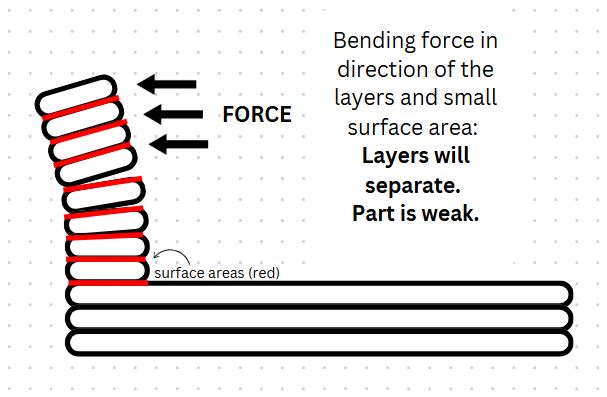

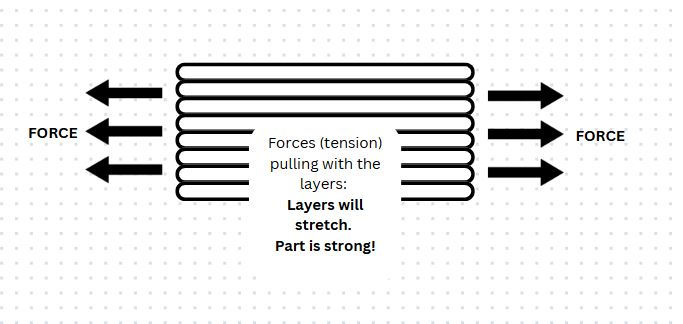

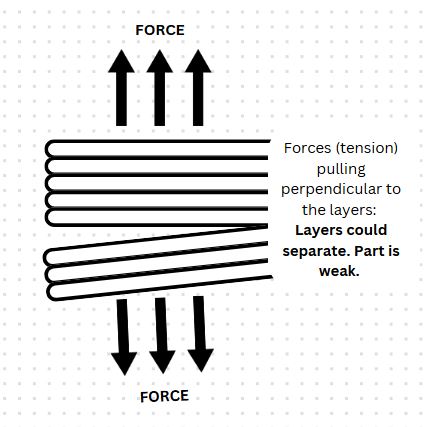

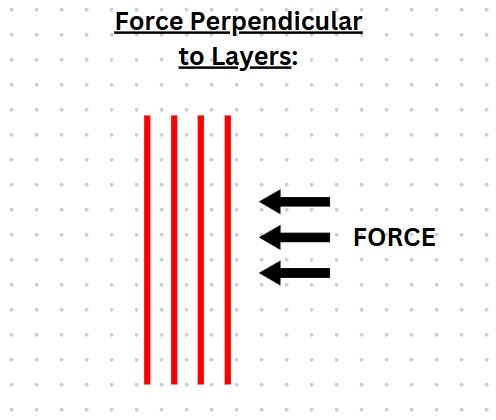

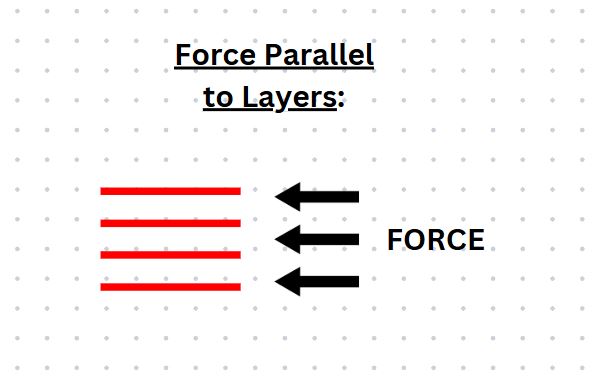

I knew that the nubs are experiencing a shear force and so I printed one of them horizontally to maximize strength, and the other vertically. Many of you might know this already, but the one printed horizontally has a larger surface layer contact which makes separating the layers much harder, aka can withstand some force. On the other hand, the one printed vertically has circular surface layers the size of the diameter and when a force is applied, could separate aka break. It’s a small part so the issue of layer separation isn’t a big one, but I wanted to flex my design skills.

Print Orientation – Engineering Principles

A Simple Bracket Example

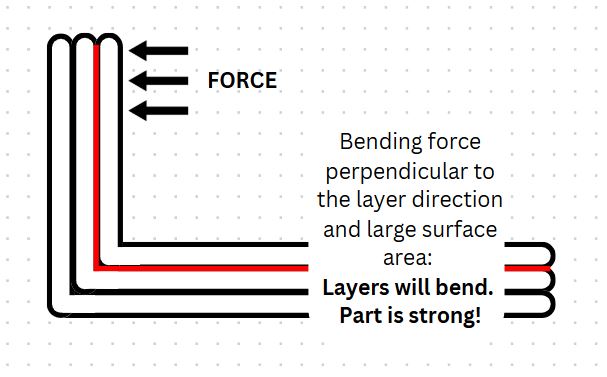

Here I arranged a bracket to be printed in two different orientations. Position #1 (left) is placed where the layer lines are all uniform AND the largest. In this orientation, the layers have the most surface area bonded to each other and therefore stronger.

the larger the layer’s surface area, the stronger the bond between them

and less likely that the layers will delaminate, or separate.

resulting in structural failure

Position # 2 (right) would result in a strong bottom, but will most likely delaminate at the top hole or that back side because the layer surface areas are smaller.

The designer of this part knew that it should be printed in position #1 and therefore accounted for the large chamfers to allow for printing without supports.

Engineering Theory of FDM 3D Printing

See this and my other simple inventions and 3D printed solutions!